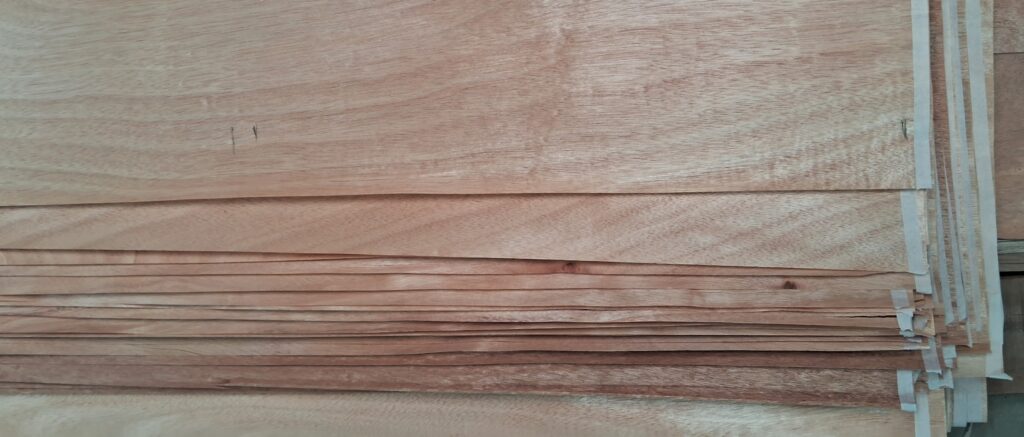

Wood veneer is a thin layer of real wood that is applied to a substrate, such as plywood or particleboard, to create a decorative finish. It is a popular choice for furniture, cabinetry, and interior surfaces due to its natural beauty, versatility, and cost-effectiveness. Veneer is created by slicing or peeling thin sheets of wood from a log, which are then bonded to a substrate using adhesive. This allows manufacturers to achieve the appearance of solid wood at a fraction of the cost. Wood veneer comes in a wide variety of species, grain patterns, and finishes, making it easy to achieve the desired aesthetic for any project. Additionally, veneer is more stable than solid wood, making it less prone to warping, splitting, or shrinking. With proper care and maintenance, wood veneer can provide a durable and timeless finish that adds warmth and character to any space.

Types Of Veneer

Wood veneer comes in various types, each offering unique characteristics and aesthetic appeal. Here are some common types of wood veneer:

1. Plain-sliced Veneer: Also known as flat-cut veneer, plain-sliced veneer is the most common type. It is sliced parallel to the tree’s growth rings, resulting in a straight grain pattern with cathedral-like arches on the surface. Plain-sliced veneer showcases the natural beauty of the wood grain and is commonly used for furniture, cabinets, and architectural millwork.

2. Quarter-sliced Veneer: Quarter-sliced veneer is produced by cutting the log into quarters and then slicing it perpendicular to the growth rings. This cutting method creates a straight grain pattern with a vertical appearance, often referred to as “ribbon-stripe” or “flake” figure. Quarter-sliced veneer is popular for its decorative effect and is commonly used for high-end furniture and architectural applications.

3. Rift-cut Veneer: Rift-cut veneer is sliced at a slight angle to the tree’s growth rings, producing a straight grain pattern with a consistent, vertical appearance. This cutting method minimizes the appearance of medullary rays and produces a more uniform grain pattern compared to quarter-sliced veneer. Rift-cut veneer is prized for its modern and elegant look and is commonly used for contemporary furniture and cabinetry.

4. Rotary-cut Veneer: Rotary-cut veneer is produced by peeling a log in a continuous spiral motion, resulting in a broad, repeating grain pattern. This cutting method allows for the production of large, seamless sheets of veneer with a varied and unpredictable grain pattern. Rotary-cut veneer is often used for budget-friendly furniture and plywood cores due to its efficiency and cost-effectiveness.

5. Burl Veneer: Burl veneer is sourced from irregular growths on trees known as burls, which feature intricate patterns and unique grain formations. Burl veneer is highly prized for its exotic appearance and distinctive character, making it a popular choice for luxury furniture, decorative accents, and musical instruments. Burl veneer adds a touch of elegance and sophistication to any application.

6. Reconstituted Veneer: Reconstituted veneer is created by bonding together thin layers of wood or paper with adhesives and then dyeing and pressing them to mimic the appearance of natural wood species. Reconstituted veneer offers consistent color and grain patterns, as well as enhanced durability and stability compared to natural wood veneer. It is available in a wide range of colors and finishes and is commonly used for decorative panels, furniture, and architectural elements.

What Is Decorative Veneer?

Decorative veneer refers to thin slices of wood that are used to enhance the aesthetic appeal of furniture, cabinetry, architectural millwork, and other interior surfaces. Unlike structural veneer, which is primarily used for its strength and durability, decorative veneer is chosen for its visual impact and decorative qualities.

Decorative veneer is typically sourced from high-quality wood species with desirable grain patterns, figures, and color variations. It is carefully selected and processed to highlight the natural beauty of the wood, showcasing its unique characteristics and enhancing the overall design of the finished product.

What Is Structural Veneer?

Structural veneer is also known as construction veneer, refers to thin sheets of wood that are primarily used for structural support and stability in construction and woodworking projects. Unlike decorative veneers, which is chosen for its aesthetic qualities, a structural veneer is selected and utilized for its strength, durability, and load-bearing capabilities.

Structural veneer is typically made from high-quality wood species that possess strong structural properties, such as birch, maple, or oak. It is produced by slicing or peeling logs into thin sheets, which are then bonded together using adhesives to form larger panels or sheets i.e Plywood, Laminated Veneer Lumber (LVL), Glued-Laminated Timber (Glulam) etc.

How To Select Veneer For Furniture?

Wood veneer is a versatile and popular choice for furniture finishes, offering a wide range of options for achieving various aesthetics and styles. When choosing veneer for furniture, several factors should be considered to ensure the desired look, quality, and durability:

Wood Species

Select a wood species that complements the design and style of the furniture piece. Popular choices include oak, walnut, cherry, maple, and mahogany, each with its unique grain pattern, color, and character. Consider the overall aesthetic you want to achieve and choose a wood species that aligns with your vision.

Grain Pattern

Veneer comes in different grain patterns, such as plain-sliced, quarter-sliced, rift-cut, and rotary-cut. Each cutting method produces distinct grain patterns, from straight and uniform to more irregular and pronounced. Consider the desired appearance and character of the wood grain when selecting veneer for furniture.

Matching Design

Pay attention to how the veneer sheets are matched and arranged on the furniture surface. Veneer matching techniques include book matching, slip matching, and random matching, each producing different visual effects. Bookmatching, for example, creates a mirror image pattern by alternating consecutive veneer sheets, while slip matching aligns consecutive sheets in the same direction. Choose a matching technique that enhances the overall design and symmetry of the furniture piece.

Color & Finish

Veneer can be stained or finished in various colors and sheens to enhance its appearance and protect it from wear and tear. Consider the desired color tone and finish for your furniture, whether it’s a natural wood tone, a rich stain, or a high-gloss lacquer. Test different finish options to see how they interact with the wood grain and complement the surrounding decor.

Quality & Thickness

Evaluate the quality and thickness of the veneer to ensure durability and longevity. High-quality veneer should be free of defects such as cracks, splits, and knots, with a consistent thickness that allows for seamless application and finishing. Thicker veneer may offer better durability and can be sanded and refinished multiple times if needed.

Budget

Consider your budget when selecting veneer for furniture, as prices can vary depending on the wood species, quality, and finish. While exotic or rare wood species may be more expensive, there are also affordable options available that offer excellent quality and aesthetic appeal. Determine your budget constraints and prioritize factors such as wood species, grain pattern, and finish accordingly.